Microsoft Acquires UK Innovator in Hollow Core Fibre Cables – Lumenisity

Global technology and software giant Microsoft has gobbled UK based Lumenisity, which was originally a spinoff from the Optoelectronics Research Centre (ORC) at the University of Southampton and specialises in developing the next generation of hollow core fibre (HCF) broadband cables.

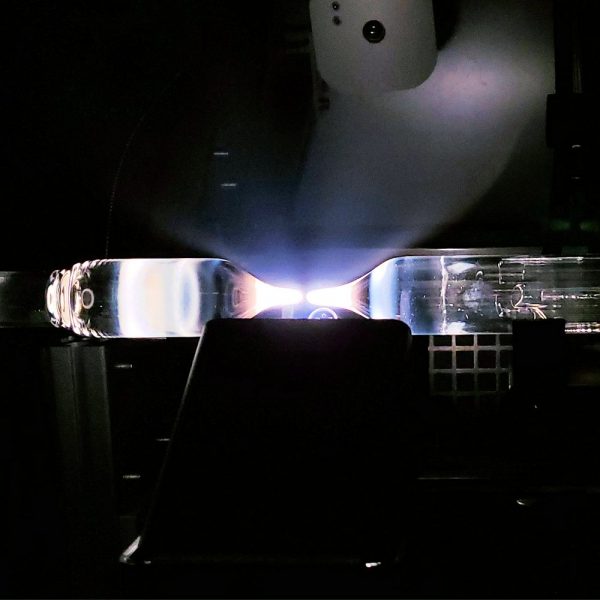

At present most conventional optical fibre cables work to guide laser light through solid glass cores, which need to be extremely transparent in order to avoid signal loss. But even the clearest of fibres will still have a slight loss over distance and solid glass fibres struggle to carry very high-power transmissions, especially in short pulses.

By comparison, hollow core fibre cables have an air-filled central core (i.e. light travels faster through the air than glass), with an outer ring of glass to help guide the beam, which helps to resolve some of the aforementioned issues – improving data speeds and latency. In relation to this, BT began working with Lumenisity to trial this inside their UK network last year (here).

Advertisement

However, Microsoft has other reasons for acquiring the company, not least of which is a desire to further optimize their global cloud infrastructure and serve Microsoft’s Cloud Platform and Services customers with strict latency and security requirements (i.e. Lumenisity’s cables have enhanced security and intrusion detection due to an innovative inner structure).

The announcement is timely, as earlier this month Lumenisity completed the development of the world’s first dedicated HCF manufacturing facility in Romsey, UK. The state-of-the art building spans 40,000 sq ft and will enable scaled-up production of HCF technology in the future. In addition, the company recently showed off their “record breaking NANF technology“, demonstrating the lowest attenuation of any HCF reported to date with losses lower than traditional solid core fibres.

Just to be absolutely clear, HCF cables aren’t going to be used to replace all of today’s optical fibres – at least not for many decades (if ever) – because we aren’t even close to maximising the capability of existing fibres. However, we will see such cables being deployed as part of future / new core network links, or for providing backhaul style capacity over longer distances etc. Gaining support from a giant like Microsoft will help to grow this.

Mark is a professional technology writer, IT consultant and computer engineer from Dorset (England), he also founded ISPreview in 1999 and enjoys analysing the latest telecoms and broadband developments. Find me on X (Twitter), Mastodon, Facebook, BlueSky, Threads.net and Linkedin.

« Virgin Media O2 UK Updates on Yorkshire Broadband and Mobile Upgrades

At last, an exciting technology moving from a British Uni to production. A pity that the company has been sold to an American company, but this is not unusual for UK tech …..sigh.

I wonder if the first task they give new apprentices is to hand them a length of ‘normal’ fibre together with an electric drill and very fine bit and tell them they need to practice creating the holes in HCF?

Oh good, yet another industry Microsoft can buy their way into and boss the competition.

I wonder how hfc is terminated / spliced and whether we could one day develop a connectorised joint terminated rather than spliced in the field?