Openreach Begin First UK Trial of Micro Ducting FTTP Deployment UPDATE

Telecoms operator Openreach (BT) has today begun trials of a “new” civil engineering technique called “Micro Ducting“, which in some areas could be used to speed up the roll-out of their new Gigabit capable Fibre-to-the-Premises (FTTP) broadband ISP technology to UK homes and businesses.

The trial was first hinted at as part of a story we ran on 10th January 2019 (here), which covered the operator’s decision to remove a batch of new 35ft tall telegraph poles after their erection caused anger among the residents of Armstrong Avenue in the suburbs of Exeter (Devon). At the time very little was known about this trial except that it had been developed in Germany.

Last week a relative (credits to Adi) of somebody living on the avenue was kind enough to pass us a copy of Openreach’s latest letter about the works, which described the trial as being a “UK first” that would take place between 13th and 20th February 2019. A total of 35 properties on the avenue are due to benefit.

Advertisement

Openreach’s Letter (Extract)

Openreach will be trialling a new micro duct system in order to provide a fibre cable to the land immediately surrounding your property (technically known as the ‘curtilage’).

The purpose of the trial is to establish whether this system would be a practical solution to provide properties which currently have a copper cable feed directly buried in the ground (like yours) with a direct fibre feed.

These works will involve excavating a small trench along the pavements and installing a micro duct and a small access box (the size of a water meter cover). All work will be completed in small sections to minimise impact and will be carried out by a specialist Openreach team.

On the surface (no pun intended) Micro Ducting sounds an awful lot like the much more familiar Micro Trenching (aka – Slot-Cutting) method of civil engineering, where a shallow and narrow trench is dug at speed into the pavement for new cables using specialist machinery. Indeed Openreach has confirmed to us that the two approaches are not radically different, barring a few changes.

Historically large cable ducts with internal diameters around 100mm were used to contain a mix of copper and fibre cables, yet building these was often a slow, disruptive and expensive process. By comparison the more familiar Micro Trenching method can save considerable time in deployment, as well as using fewer resources, reducing environmental impact (i.e. less waste removed from trenches or transported to the site for backfill).

In the past we’ve seen Micro Trenching where an operator has laid conduits into a slot-cut trench of less than 20mm wide and between 120-300mm deep. Meanwhile Openreach’s team will be using specialist kit to dig in via a twin saw so that both sides of the channel can be cut at the same time; this process cuts a narrow trench about 4 inches wide (100mm) and to about 250mm depth or below.

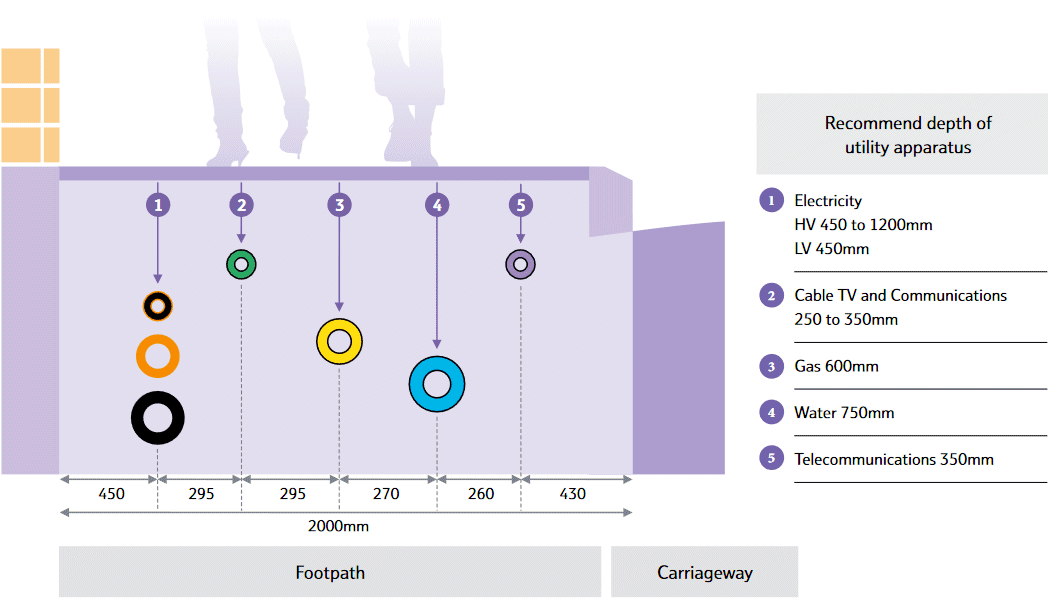

Just for some context, here’s an Openreach illustration of how deep different ducts usually go (TV/comms networks tend to be around 250-350mm).

Advertisement

One key difference with Openreach’s method is that the fibre cable can be pushed down the micro-duct rather than having to be blown (often cheaper) and the kit works with their existing connectorized fibre. The silicon lined micro-ducting is also armoured (comes in 3m sections) because it needs to be robust enough to go direct into the ground.

The downside of pushing cables is that you can’t reach as far as the blown method, although an earlier pilot has shown that Openreach could push the cable up to a distance of 80-100m. The “slippery fish” cables they use (a 2-fibre small profile oval cross-sectional cable of 8x4mm) are quite rigid and strong enough to be pushed over that distance without bending or snagging. They’re also small enough to clip onto poles or slip behind other cables or trunking.

At the time of writing we haven’t been able to get any detail on comparative costings from Openreach, although more traditional / older methods of civil engineering were known to cost in the order of £75-125 per metre and a single gang would typically complete 30-50m a day.

Advertisement

By comparison even older styles of Micro Trenching used approximately one hundredth of the material needed to backfill the trench and, where the technique is appropriate, typical costs were in the order of £10-15 per metre and a single gang could complete 150-200m per day.

At this stage we don’t know how fast Openreach can go with Micro Ducting and trial itself may go slower for the purpose of learning. Likewise the size of the trench makes us think that Micro Ducting may be more expensive than c.£10-15 per metre via Micro Trenching, but we’ll probably only know for sure if it leaves the trial phase.

Openreach informs us that the trial will last for a month (just deployment takes a week) and then they’ll collect the data, which will be used to decide whether there’s a business case to continue with it. Apparently they’re only trialling this in areas that do not have existing infrastructure, which we assume means FTTP since Armstrong Avenue does have cables (e.g. Virgin Media) that will need to be very carefully avoided.

Otherwise the operator is currently building in Exeter at a rate of 500 homes passed per week and they’ve already covered 10,000 since the work began.

UPDATE 9:25am

Openreach are using a 36 fibre cable for Exeter but with this method they could use up to 144 fibres, not that this is an issue since every fibre can support 32 FTTP connections. In addition, the operator has informed us that they’re also testing Micro Ducting on a deployment to 160 premises in Ashford, Kent. Now here’s a picture of the machine they’re using.

UPDATE 15th Feb 2019

We’ve had some pictures of the local engineering work, which shows quite a bit of disruption and the use of the word “micro” is being called a bit into question with those trench sizes.

Mark is a professional technology writer, IT consultant and computer engineer from Dorset (England), he also founded ISPreview in 1999 and enjoys analysing the latest telecoms and broadband developments. Find me on X (Twitter), Mastodon, Facebook, BlueSky, Threads.net and Linkedin.

« First British 5G Mobile Smart Factory Trials Go Live in Worcestershire

Nominet UK Launch New Tool to Help TVWS Wireless Networks »

Comments are closed